CS/MS FLANGE

CS/MS FLANGE

Our CS and MS Flanges are designed to meet the demands of industries such as oil & gas, petrochemicals, power generation, construction, and water treatment. Available in a wide variety of sizes, specifications, and pressure ratings, our flanges are perfect for applications requiring secure pipe connections, leak-proof sealing, and high resistance to wear and corrosion.

With state-of-the-art manufacturing facilities and stringent quality control processes, we ensure that every product adheres to international standards and exceeds client expectations. Whether you need customized solutions or bulk supplies, we provide competitive pricing, prompt delivery, and unparalleled customer support. Partner with us for reliable CS and MS flange solutions tailored to your needs.

Features of MS Flanges

- Flange-like Design: Flanges have a but weld, threaded & socket-like design that allows the pipe to be inserted into the flange.

- Welded Connection: They are designed to be welded to the end of a pipe, creating a secure and leak-proof connection.

- High Strength: Flanges offer high strength and durability.

- Resistant to Corrosion: They are resistant to corrosion and can withstand harsh environments.

Benefits of Flanges

- Secure Connection: Flanges provide a secure and leak-proof connection.

- High Pressure Resistance: They can withstand high pressures and temperatures.

- Low Maintenance: Flanges require minimal maintenance.

- Cost-Effective: They are a cost-effective solution for piping connections.

Applications of Flanges

- Oil and Gas Industry: Flanges are used in the oil and gas industry for piping connections.

- Chemical Industry: They are used in the chemical industry to handle corrosive fluids.

- Power Plants: Flanges are used in power plants for high-pressure piping connections.

- Other Industrial Applications: They are used in various other industrial applications, including water treatment, pharmaceuticals, and food processing.

Types of Flanges

Slip On Flange

A Slip-On Flange is a type of flange that is slipped over the end of a pipe and welded in place. It has a hole that matches the pipe's diameter and is designed to fit snugly over the pipe.

Weld Neck Flange

A Weld Neck Flange is a type of flange that is designed to be welded to the end of a pipe. It has a long neck that is tapered to match the pipe's diameter, allowing for a strong and secure weld.

Blind Flange

A Blind Flange is a type of flange that is used to seal the end of a pipe or a vessel. It is a solid, flat disc with a flange on the back that is used to bolt it to another flange or a vessel.

Threaded Flange

A Threaded Flange is a type of flange that has a threaded connection, allowing it to be screwed onto a pipe or a fitting. It is designed to provide a secure and leak-proof connection.

Socket Flange

A Socket Weld Flange is a type of flange that is designed to be welded to the end of a pipe. It has a socket-like design that allows the pipe to be inserted into the flange, creating a secure and leak-proof connection.

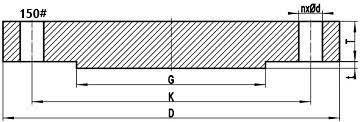

DIMENSION OF PIPE FLANGES AS PER TABLE BS- 10

Table D: For Working Steam Pressure upto 50 Ibs per sq. inch

Nominal |

O.D of |

Dia. of |

Dia. of |

No. of |

Dia. of |

Thickness |

Pipe size |

Pipe |

Flange |

Bolt Circle |

Bolt |

Bolt |

|

1/2" |

21.3 |

95.3 |

66.7 |

4 |

12.7 |

4.8 |

3/4" |

26.7 |

101.6 |

73.0 |

4 |

12.7 |

4.8 |

1" |

33.4 |

114.3 |

82.6 |

4 |

12.7 |

4.8 |

1 1/4" |

42.2 |

120.7 |

87.6 |

4 |

12.7 |

6.4 |

1 1/2" |

48.3 |

133.4 |

98.4 |

4 |

12.7 |

6.4 |

2" |

60.3 |

152.4 |

114.3 |

4 |

15.9 |

7.9 |

2 1/2" |

73.0 |

165.1 |

127.0 |

4 |

15.9 |

7.9 |

3" |

88.9 |

184.2 |

146.1 |

4 |

15.9 |

9.5 |

3 1/2" |

101.6 |

203.2 |

165.1 |

4 |

15.9 |

9.5 |

4" |

114.3 |

215.9 |

177.8 |

4 |

15.9 |

9.5 |

5" |

141.3 |

254.0 |

209.6 |

8 |

15.9 |

12.7 |

6" |

168.3 |

279.4 |

228.6 |

8 |

15.9 |

12.7 |

7" |

190.5 |

304.8 |

260.4 |

8 |

15.9 |

12.7 |

8" |

219.1 |

336.6 |

292.1 |

8 |

15.9 |

12.7 |

9" |

244.5 |

368.3 |

323.9 |

8 |

15.9 |

15.9 |

10" |

273.0 |

406.4 |

355.6 |

8 |

19.1 |

15.9 |

12" |

323.9 |

457.2 |

406.4 |

12 |

19.1 |

15.9 |

14" |

355.6 |

527.1 |

469.9 |

12 |

22.2 |

19.1 |

16" |

406.4 |

577.9 |

520.7 |

12 |

22.2 |

19.1 |

18" |

457.2 |

641.4 |

584.2 |

12 |

22.2 |

22.2 |

20" |

508.0 |

704.9 |

641.4 |

16 |

22.5 |

25.4 |

24" |

609.6 |

825.5 |

755.7 |

16 |

25.4 |

28.6 |

Table E: For Working Steam Pressure 50 Ibs upto 100 Ibs per sq. inch

Nominal |

Dia. of |

Dia. of |

No. of |

Dia. of |

Thickness |

Pipe Size |

Flange |

Bolt Circle |

Bolt |

Bolt |

|

1/2" |

95.3 |

66.7 |

4 |

12.7 |

6.4 |

3/4" |

101.6 |

73.0 |

4 |

12.7 |

6.4 |

1" |

114.3 |

82.6 |

4 |

12.7 |

7.1 |

1 1/4" |

120.7 |

87.3 |

4 |

12.7 |

7.9 |

1 1/2" |

133.4 |

98.4 |

4 |

12.7 |

8.7 |

2" |

152.4 |

114.3 |

4 |

15.9 |

9.5 |

2 1/2" |

165.1 |

127.0 |

4 |

15.9 |

10.3 |

3" |

184.2 |

146.1 |

4 |

15.9 |

11.1 |

3 1/2" |

203.2 |

165.1 |

8 |

15.9 |

11.9 |

4" |

215.9 |

177.8 |

8 |

15.9 |

12.7 |

5" |

254.0 |

209.6 |

8 |

15.9 |

14.3 |

6" |

279.4 |

228.6 |

8 |

19.1 |

17.5 |

7" |

304.8 |

260.4 |

8 |

19.1 |

19.1 |

8" |

336.6 |

292.1 |

8 |

19.1 |

19.1 |

9" |

368.3 |

323.9 |

12 |

19.1 |

20.6 |

10" |

406.4 |

355.6 |

12 |

19.1 |

22.2 |

12" |

457.2 |

406.4 |

12 |

22.2 |

25.4 |

14" |

527.2 |

469.9 |

12 |

22.2 |

25.4 |

16" |

577.9 |

520.7 |

12 |

22.2 |

25.4 |

18" |

641.4 |

584.2 |

16 |

22.2 |

28.6 |

20" |

704.9 |

647.4 |

16 |

22.2 |

31.8 |

24" |

825.5 |

755.7 |

16 |

25.4 |

38.1 |

Table F: For Working Steam Pressure above 100 Ibs and upto 150 Ibs per sq. inch

Nominal |

O.D. of |

Dia of |

Dia of |

No. of |

Dia. of |

Thickness |

Pipe Size |

Pipe |

Flange |

Bolt Circle |

Bolt |

Bolt |

|

1/2" |

21.3 |

95.3 |

66.7 |

4 |

12.7 |

9.5 |

3/4" |

26.7 |

101.6 |

73.0 |

4 |

12.7 |

9.5 |

1" |

33.4 |

120.7 |

87.3 |

4 |

15.9 |

9.5 |

1 1/4" |

42.2 |

133.4 |

98.4 |

4 |

15.9 |

12.7 |

1 1/2" |

48.3 |

139.7 |

104.8 |

4 |

15.9 |

12.7 |

2" |

60.3 |

165.1 |

127.0 |

4 |

15.9 |

15.9 |

2 1/2" |

73.0 |

184.2 |

146.1 |

8 |

15.9 |

15.9 |

3" |

88.9 |

203.2 |

165.1 |

8 |

15.9 |

15.9 |

3 1/2" |

101.6 |

215.9 |

177.8 |

8 |

15.9 |

19.1 |

4" |

114.3 |

228.6 |

190.5 |

8 |

15.9 |

19.1 |

5" |

141.3 |

279.4 |

235.0 |

8 |

19.1 |

22.2 |

6" |

168.3 |

304.8 |

260.4 |

12 |

19.1 |

22.2 |

7" |

190.3 |

336.6 |

292.1 |

12 |

19.1 |

22.2 |

8" |

219.1 |

368.3 |

323.9 |

12 |

19.1 |

25.4 |

9" |

244.5 |

406.4 |

355.6 |

12 |

22.2 |

25.4 |

10" |

273.0 |

431.8 |

381.0 |

12 |

22.2 |

25.4 |

12" |

323.0 |

489.0 |

438.2 |

16 |

22.2 |

28.6 |

14" |

355.6 |

552.5 |

495.3 |

16 |

25.4 |

31.8 |

16" |

406.4 |

609.6 |

552.5 |

20 |

25.4 |

31.8 |

18" |

457.2 |

673.1 |

609.6 |

20 |

28.6 |

34.9 |

20" |

508.0 |

736.6 |

673.1 |

24 |

28.6 |

38.1 |

24" |

609.6 |

850.9 |

781.1 |

24 |

31.8 |

41.3 |

Table H: For Working Steam Pressure above 150 Ibs and upto 250 Ibs per sq. inch

Nominal |

Dia of |

Dia. of |

No. of |

Dia. of |

Thickness |

Pipe size |

Flange |

Bolt Circle |

Bolt |

Bolt |

|

1/2" |

114.3 |

82.6 |

4 |

15.9 |

12.7 |

3/4" |

114.3 |

82.6 |

4 |

15.9 |

12.7 |

1" |

120.78 |

87.3 |

4 |

15.9 |

14.3 |

1 1/4" |

133.4 |

98.4 |

4 |

15.9 |

17.5 |

1 1/2" |

139.7 |

104.8 |

4 |

15.9 |

17.5 |

2" |

165.1 |

127.0 |

4 |

15.9 |

19.1 |

2 1/2" |

184.2 |

146.1 |

8 |

15.9 |

19.1 |

3" |

203.2 |

165.1 |

8 |

15.9 |

22.2 |

3 1/2" |

215.9 |

177.8 |

8 |

15.9 |

22.2 |

4" |

228.6 |

190.5 |

8 |

15.9 |

25.4 |

5" |

279.4 |

235.0 |

8 |

19.1 |

28.6 |

6" |

304.8 |

260.4 |

12 |

19.1 |

28.6 |

7" |

336.6 |

292.1 |

12 |

19.1 |

31.8 |

8" |

368.3 |

323.9 |

12 |

19.1 |

31.8 |

9" |

406.4 |

355.6 |

12 |

22.2 |

34.9 |

10" |

431.8 |

381.0 |

12 |

22.2 |

34.9 |

12" |

489.0 |

438.2 |

16 |

22.2 |

38.1 |

14" |

552.5 |

495.3 |

16 |

25.4 |

41.3 |

16" |

609.6 |

552.5 |

20 |

25.4 |

44.5 |

18" |

673.1 |

609.6 |

20 |

28.6 |

47.6 |

20" |

736.6 |

673.1 |

24 |

28.6 |

50.8 |

24" |

850.9 |

781.1 |

24 |

31.8 |

57.2 |

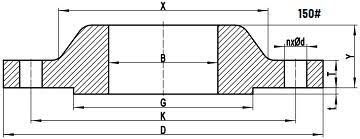

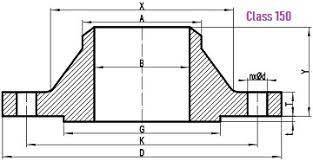

FORGED FLANGES TO ANSI B 16.5 (ASA 150 / 300 LBS)

Slip On Flange

Welding Neck Flange

Blind Flange

150 LBS

Nominal |

Flange |

Dia of |

Dia of |

Length through Hub |

Dia of Bore |

|||||||||

Pipe Size |

Pipe size |

Dia |

Bolt |

Bolt |

No. of |

Thk. of |

Dia of |

S/O & S/W |

W/N |

L/J |

S/O & S/W |

L/J |

Dia of |

Depth of |

Circle |

Holes |

Holes |

Flange |

Hub |

R/F |

Socket |

||||||||

(MM) |

(INCH.) |

O |

A |

D |

C |

E |

Y |

Y |

Y |

B |

B |

R |

F |

|

15 |

1/2 |

88.9 |

60.3 |

15.9 |

4 |

11.1 |

30.2 |

15.9 |

47.6 |

15.9 |

22.3 |

22.9 |

34.9 |

9.5 |

20 |

3/4 |

98.4 |

69.8 |

15.9 |

4 |

12.7 |

38.1 |

15.9 |

52.4 |

15.9 |

27.7 |

28.2 |

42.9 |

11.1 |

25 |

1 |

107.9 |

79.4 |

15.9 |

4 |

14.3 |

49.2 |

17.5 |

55.6 |

17.5 |

34.5 |

35.0 |

50.8 |

12.7 |

32 |

1 1/4 |

117.5 |

88.9 |

15.9 |

4 |

15.9 |

58.7 |

20.6 |

57.1 |

20.6 |

43.2 |

43.7 |

63.5 |

14.3 |

40 |

1 1/2 |

127.0 |

98.4 |

15.9 |

4 |

17.5 |

65.1 |

22.2 |

61.9 |

22.2 |

49.5 |

50.0 |

73.0 |

15.9 |

50 |

2 |

152.4 |

120.6 |

19.0 |

4 |

19.0 |

77.8 |

25.4 |

63.5 |

25.4 |

62.0 |

62.5 |

92.1 |

17.5 |

65 |

2 1/2 |

177.8 |

139.7 |

19.0 |

4 |

22.2 |

90.5 |

28.6 |

69.8 |

28.6 |

74.7 |

75.4 |

104.8 |

19.0 |

80 |

3 |

190.5 |

152.4 |

19.0 |

4 |

23.8 |

107.9 |

30.2 |

69.8 |

30.2 |

90.7 |

91.4 |

127.0 |

20.6 |

100 |

4 |

228.6 |

190.5 |

19.0 |

8 |

23.8 |

134.9 |

33.3 |

76.2 |

33.3 |

116.1 |

116.8 |

157.2 |

23.8 |

125 |

5 |

254.0 |

215.9 |

22.2 |

8 |

23.8 |

163.5 |

36.5 |

88.9 |

36.5 |

143.8 |

144.5 |

185.7 |

23.8 |

150 |

6 |

279.4 |

241.3 |

22.2 |

8 |

25.4 |

192.1 |

39.7 |

88.9 |

39.7 |

170.7 |

171.4 |

215.9 |

27.0 |

200 |

8 |

342.9 |

298.4 |

22.2 |

8 |

28.6 |

246.1 |

44.4 |

101.6 |

44.4 |

221.5 |

222.2 |

269.9 |

31.7 |

250 |

10 |

406.4 |

361.9 |

25.4 |

12 |

30.2 |

304.8 |

49.2 |

101.6 |

49.2 |

276.3 |

277.4 |

323.8 |

33.3 |

300 |

12 |

482.6 |

431.8 |

25.4 |

12 |

31.8 |

365.1 |

55.6 |

114.3 |

55.6 |

327.1 |

328.2 |

381.0 |

39.7 |

350 |

14 |

533.4 |

476.2 |

28.6 |

12 |

34.9 |

400.0 |

57.1 |

127.0 |

79.4 |

359.1 |

360.2 |

412.7 |

41.3 |

400 |

16 |

596.9 |

539.7 |

28.6 |

16 |

36.5 |

457.2 |

63.5 |

127.0 |

87.3 |

410.5 |

411.2 |

469.9 |

44.4 |

450 |

18 |

635.0 |

577.8 |

31.7 |

16 |

39.7 |

504.8 |

68.3 |

139.7 |

96.8 |

461.8 |

462.3 |

533.4 |

49.2 |

500 |

20 |

698.5 |

635.0 |

31.7 |

20 |

42.9 |

558.8 |

73.0 |

144.5 |

103.2 |

513.1 |

514.3 |

584.2 |

54.0 |

600 |

24 |

812.8 |

749.3 |

34.9 |

20 |

47.6 |

663.6 |

82.5 |

152.4 |

111.1 |

615.9 |

615.9 |

692.1 |

63.5 |

300 LBS

Length through Hub |

Dia of Bore |

|||||||||||||

Nominal Pipe |

Flange Dia |

Dia of Bolt |

Dia of Bolt |

No. of |

Thk. of |

Dia of |

S/O & S/W |

W/N |

L/J |

S/O & S/W |

L/J |

Dia of |

Depth of |

|

Size |

Circle |

Holes |

Holes |

Flange |

Hub |

R/F |

Socket |

|||||||

(MM) |

(INCH.) |

O |

A |

D |

C |

E |

Y |

Y |

Y |

B |

B |

R |

F |

|

15 |

1/2 |

95.2 |

66.7 |

15.9 |

4 |

14.3 |

38.1 |

22.2 |

52.4 |

22.2 |

22.3 |

22.9 |

34.9 |

9.5 |

20 |

3/4 |

117.5 |

82.5 |

19.0 |

4 |

15.9 |

47.6 |

25.4 |

57.1 |

25.4 |

27.7 |

28.2 |

42.9 |

11.1 |

25 |

1 |

123.8 |

88.9 |

19.0 |

4 |

17.5 |

54.0 |

27.0 |

61.9 |

27.0 |

34.5 |

35.0 |

50.8 |

12.7 |

32 |

1 1/4 |

133.3 |

98.4 |

19.0 |

4 |

19.0 |

63.5 |

27.0 |

65.1 |

27.0 |

43.2 |

43.7 |

63.5 |

14.3 |

40 |

1 1/2 |

155.6 |

114.3 |

22.2 |

4 |

20.6 |

69.8 |

30.2 |

68.3 |

30.2 |

49.5 |

50.0 |

73.0 |

15.9 |

50 |

2 |

165.1 |

127.0 |

19.0 |

8 |

22.2 |

84.1 |

33.3 |

69.8 |

33.3 |

62.0 |

62.5 |

92.1 |

17.5 |

65 |

2 1/2 |

190.5 |

149.2 |

22.2 |

8 |

25.4 |

100.0 |

38.1 |

76.2 |

38.1 |

74.7 |

75.4 |

104.8 |

19.0 |

80 |

3 |

209.5 |

168.3 |

22.2 |

8 |

28.6 |

117.5 |

42.9 |

79.4 |

42.9 |

90.7 |

91.4 |

127.0 |

20.6 |

100 |

4 |

254.0 |

200.0 |

22.2 |

8 |

31.8 |

146.0 |

47.6 |

85.7 |

47.6 |

116.1 |

116.8 |

157.2 |

23.8 |

125 |

5 |

279.4 |

234.9 |

22.2 |

8 |

34.9 |

177.8 |

50.8 |

98.4 |

50.8 |

143.8 |

144.5 |

185.7 |

- |

150 |

6 |

317.5 |

269.9 |

22.2 |

12 |

36.5 |

206.4 |

52.4 |

98.4 |

52.4 |

170.7 |

171.4 |

215.9 |

- |

200 |

8 |

381.0 |

330.2 |

25.4 |

12 |

41.3 |

260.3 |

61.9 |

111.1 |

61.9 |

221.5 |

222.2 |

269.9 |

- |

250 |

10 |

444.5 |

387.3 |

28.6 |

16 |

47.6 |

320.7 |

66.7 |

117.5 |

95.2 |

276.3 |

277.4 |

323.8 |

- |

300 |

12 |

520.7 |

450.8 |

31.7 |

16 |

50.8 |

374.6 |

73.0 |

130.2 |

101.6 |

327.1 |

328.2 |

381.0 |

- |

350 |

14 |

584.2 |

514.3 |

31.7 |

20 |

54.0 |

425.4 |

76.2 |

142.9 |

111.1 |

359.1 |

360.2 |

412.7 |

- |

400 |

16 |

647.7 |

571.5 |

34.9 |

20 |

57.2 |

482.6 |

82.5 |

146.0 |

120.6 |

410.5 |

411.2 |

469.9 |

- |

450 |

18 |

711.2 |

628.5 |

34.9 |

24 |

60.3 |

533.4 |

88.9 |

158.7 |

130.2 |

461.8 |

462.3 |

533.4 |

- |

500 |

20 |

774.7 |

685.8 |

34.9 |

24 |

63.5 |

587.4 |

95.2 |

161.9 |

139.7 |

513.1 |

514.3 |

584.2 |

- |

600 |

24 |

914.4 |

812.8 |

41.3 |

24 |

69.8 |

701.7 |

106.4 |

168.3 |

152.4 |

615.9 |

615.9 |

692.1 |

- |

Why Choose Siemens Metal & Tubes

EXPERIENCE

We have an experience of over 15 Years in dealing with this Industries.FAST DELIVERY

Collaborate Our Company

Products of superior quality at very affordable charges.

Completed Projects

Work With Us

Idea Realized

Our Clients Say’s

ISRAR AHMED

Venkat Raman

Gayatri Electrical Engg

Would You Like To Know More?

Why Choose Us

Precision and Quality:

Customization Expertise:

Sustainability and Innovation:

-

What types of metals are commonly used in the industry?Common metals include steel, stainless steel, aluminum, copper, brass, bronze, titanium, and various alloys. The choice of metal depends on the application, strength, corrosion resistance, weight, and cost requirements.

-

What quality standards are followed in metal manufacturing?Metal industries often adhere to international quality standards like ISO 9001 for general quality management, ASME standards for pressure vessels, ASTM standards for material specifications, and ISO 14001 for environmental management. Industry-specific standards may also apply depending on the project.

-

Can metal industries handle custom projects and prototypes?Yes, many metal industries specialize in custom projects and prototyping. They work closely with clients to design and manufacture tailored solutions, leveraging expertise in design, material selection, and advanced manufacturing processes.

Need Any Help

To Choose The Right Product

Need Any Help

To Choose The Right Product