15

Thane, Maharashtra

GST No. 27ABXPI2016G1ZM

Call: +91-9838347523 | +91-9616170558

CS/MS PIPE

Our Products

CS/MS PIPE

applications. Known for their superior durability, strength, and corrosion resistance, our pipes are engineered to meet stringent quality standards and deliver excellent performance.

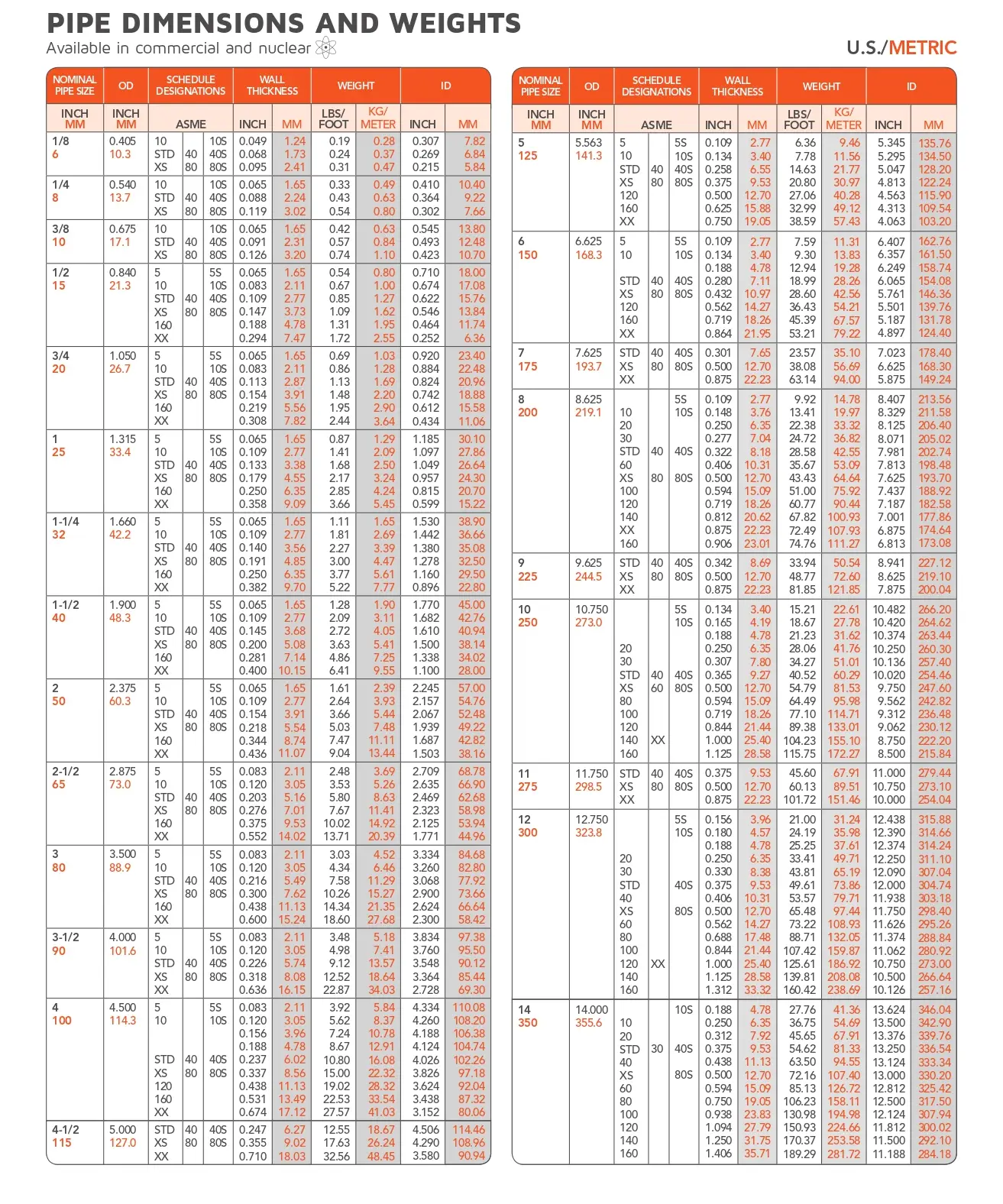

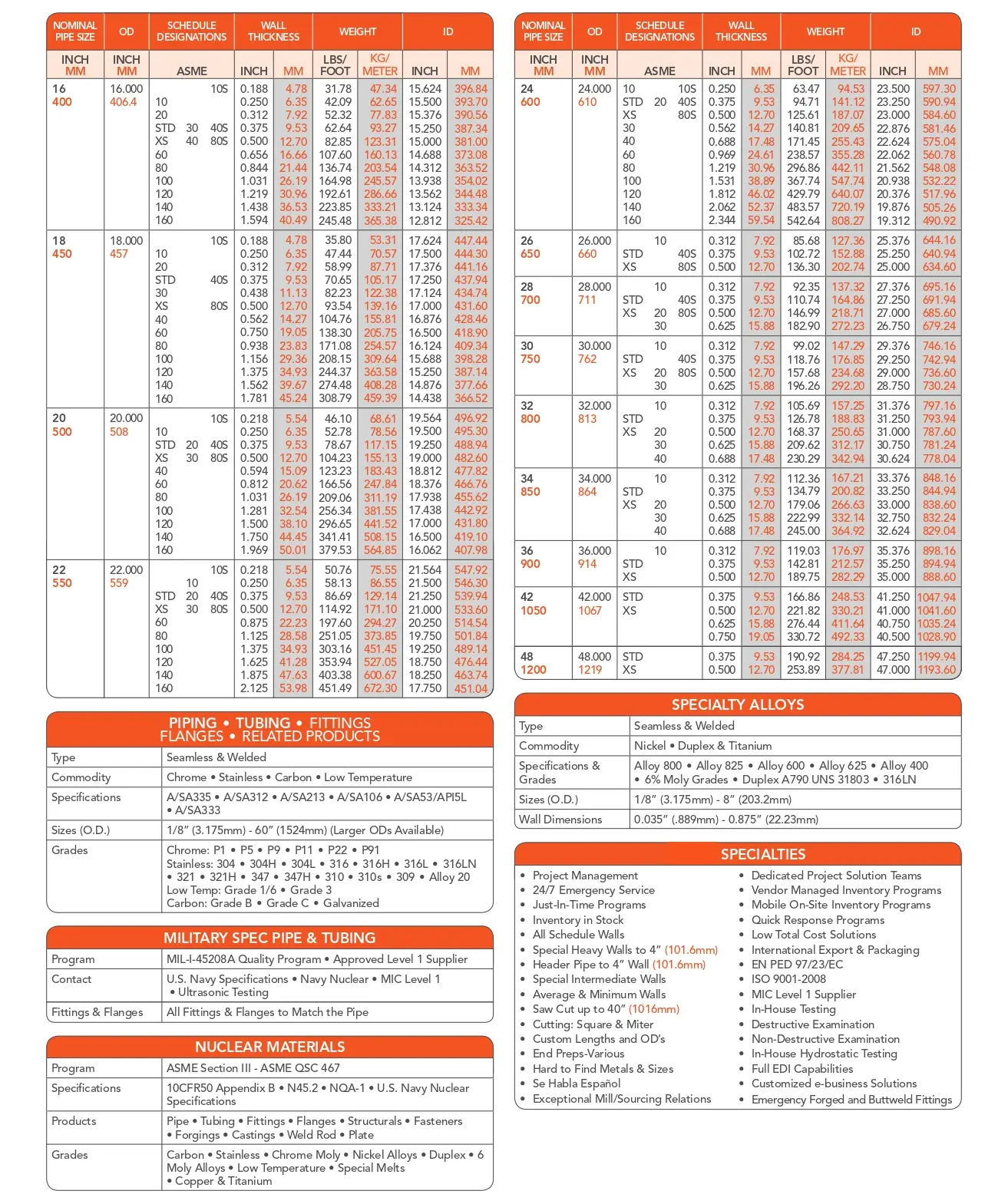

Our CS and MS Pipes are available in various sizes, thicknesses, and specifications to cater to industries such as construction, oil & gas, water transportation, power generation, and infrastructure. These pipes are ideal for structural, fluid transportation, and general engineering applications due to their high tensile strength and adaptability to demanding environments.

Backed by advanced manufacturing processes and strict quality control measures, we ensure that our pipes provide long-lasting and cost-effective solutions. With competitive pricing, bulk supply capabilities, and timely delivery, we are committed to exceeding customer expectations.

Choose us for your CS and MS pipe requirements and experience unmatched service and quality.

Our CS and MS Pipes are available in various sizes, thicknesses, and specifications to cater to industries such as construction, oil & gas, water transportation, power generation, and infrastructure. These pipes are ideal for structural, fluid transportation, and general engineering applications due to their high tensile strength and adaptability to demanding environments.

Backed by advanced manufacturing processes and strict quality control measures, we ensure that our pipes provide long-lasting and cost-effective solutions. With competitive pricing, bulk supply capabilities, and timely delivery, we are committed to exceeding customer expectations.

Choose us for your CS and MS pipe requirements and experience unmatched service and quality.

For Enquire Purpose

+91-9838347523

High Quality Solutions

Why Choose Siemens Metal & Tubes

EXPERIENCE

We have an experience of over 15 Years in dealing with this Industries.FAST DELIVERY

Our high production capacity Helps us to give on time deliveries no compromising on quality.

NUMBERS SPEAK

Collaborate Our Company

Our business takes pride in giving Pipe Fittings and Other Mild Steel & Stainless Steel

Products of superior quality at very affordable charges.

Products of superior quality at very affordable charges.

0

Completed Projects

0

Work With Us

0

Idea Realized

TESTIMONIALS

Our Clients Say’s

I am very impressed with the service Of Siemens Metal & Tubes, placed an order and it arrived this on time.

ISRAR AHMED

Thane, Maharashtra

Very impressed with how proactive they are. Very friendly people and super efficient. Products quality is very good.

Venkat Raman

Chennai, Tamil Nadu

Excellent service and really quick delivery. It's so hard to find quality products.

Gayatri Electrical Engg

Sonipat, Haryana

Siemens Metal & Tubes

Would You Like To Know More?

We prioritize precision, durability, and the highest quality standards in all our products.

Our Services

Why Choose Us

Precision and Quality:

We deliver high-quality metal products with advanced machinery, strict quality control, and adherence to industry standards for reliable performance.

Customization Expertise:

From prototypes to large-scale production, we offer tailored solutions to meet your unique requirements with precision and efficiency.

Sustainability and Innovation:

Committed to eco-friendly practices, we combine cutting-edge technologies and sustainable methods to ensure superior results.

-

What types of metals are commonly used in the industry?Common metals include steel, stainless steel, aluminum, copper, brass, bronze, titanium, and various alloys. The choice of metal depends on the application, strength, corrosion resistance, weight, and cost requirements.

-

What quality standards are followed in metal manufacturing?Metal industries often adhere to international quality standards like ISO 9001 for general quality management, ASME standards for pressure vessels, ASTM standards for material specifications, and ISO 14001 for environmental management. Industry-specific standards may also apply depending on the project.

-

Can metal industries handle custom projects and prototypes?Yes, many metal industries specialize in custom projects and prototyping. They work closely with clients to design and manufacture tailored solutions, leveraging expertise in design, material selection, and advanced manufacturing processes.

Need Any Help

To Choose The Right Product

Need Any Help

To Choose The Right Product